- Home

-

Product & Service

Our products and services cover four major categories of industrial Internet of Things (IIoT), manufacturing equipment, industrial trade and technical services. Our customers are in the manufacturing fields of automobile, aerospace, energy, ship and railway, construction machinery, electrical machinery and equipment, electronics and communications equipment and various types of equipment and machinery.

IIoT products include IIoT system platforms, sensor systems and industrial management software. Manufacturing equipment includes various advanced manufacturing industrial equipment and auxiliary machines. Through the global sales and service network, we can provide professional and fast international industrial trading services, introduce advanced technologies and industrial products from countries such as Germany and the United States, and export industrial products made in China to Europe and the Americas. We provide a full range of technical services for self-built products and partner products. Service first is always one of the core of our product elements.

Please pay attention to our products and services! If you need more detailed product and service introduction, please contact us.

-

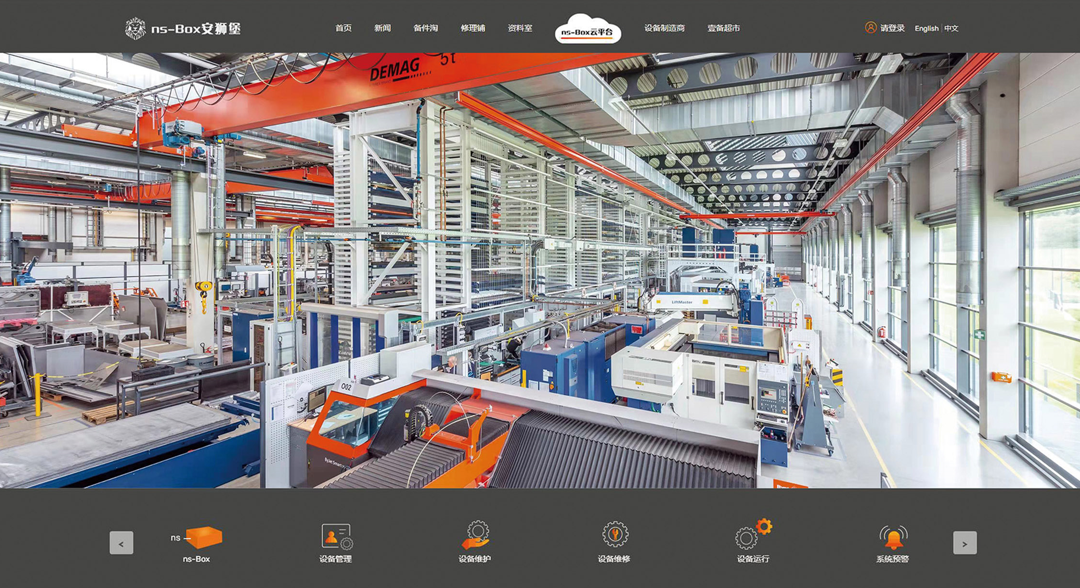

ns-Box System

ns-Box system is built on the basis of big data and cloud computing for industrial equipment MRO management and applied for professional maintenance, repair and operation management of CNC machine tools and other industrial equipment. Through data collection and securing system, ns-Box can help enterprises build up IIoT and MES ...

Read more >>

-

ns-IIoT Equipment IoT Platform

The ns-IIoT industrial equipment IoT platform conforms to the development trend of Industry 4.0, is oriented to manufacturing enterprises, and connects various industrial equipment within the enterprise through various sensing technologies, gateways and application software ...

Read more >>

-

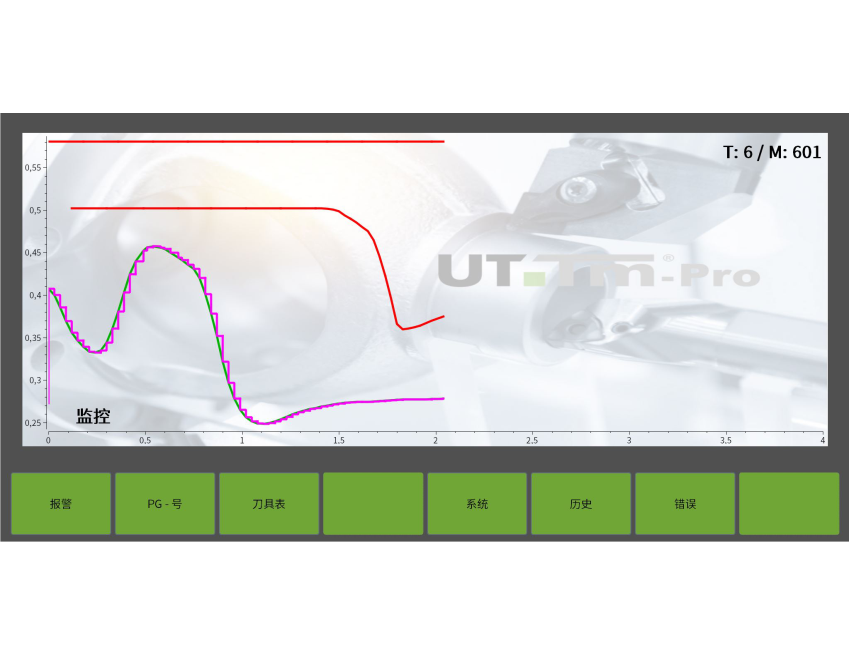

Tool Monitoring System

NUOSUN cooperates with the German UTTec company to introduce CNC machine tool monitoring system ns-UTTec to Chinese market. This system can monitor the working life of the machine tool spindle in real time for data analysis ...

Read more >>

-

KNOLL Machine Tool Filter|Chip Conveyor|Pumping Station|Chip Reducer|High-pressure Supply|Heavy-duty Conveying System

-

BEP Vacuum Evaporation for Industrial Wastewater

-

-

STA Industrial Centrifuge

-

Walter Rotary Table for Machine Tools

Our products and services cover four major categories of industrial Internet of Things (IIoT), manufacturing equipment, industrial trade and technical services. Our customers are in the manufacturing fields of automobile, aerospace, energy, ship and railway, construction machinery, electrical machinery and equipment, electronics and communications equipment and various types of equipment and machinery.

IIoT products include IIoT system platforms, sensor systems and industrial management software. Manufacturing equipment includes various advanced manufacturing industrial equipment and auxiliary machines. Through the global sales and service network, we can provide professional and fast international industrial trading services, introduce advanced technologies and industrial products from countries such as Germany and the United States, and export industrial products made in China to Europe and the Americas. We provide a full range of technical services for self-built products and partner products. Service first is always one of the core of our product elements.

Please pay attention to our products and services! If you need more detailed product and service introduction, please contact us.

Our products and services cover four major categories of industrial Internet of Things (IIoT), manufacturing equipment, industrial trade and technical services. Our customers are in the manufacturing fields of automobile, aerospace, energy, ship and railway, construction machinery, electrical machinery and equipment, electronics and communications equipment and various types of equipment and machinery.

IIoT products include IIoT system platforms, sensor systems and industrial management software. Manufacturing equipment includes various advanced manufacturing industrial equipment and auxiliary machines. Through the global sales and service network, we can provide professional and fast international industrial trading services, introduce advanced technologies and industrial products from countries such as Germany and the United States, and export industrial products made in China to Europe and the Americas. We provide a full range of technical services for self-built products and partner products. Service first is always one of the core of our product elements.

Please pay attention to our products and services! If you need more detailed product and service introduction, please contact us.

-

- Applicaiton

- Company

- Contact